Seven Important Reasons Why Proto-Cutter Should Be Your Source for Coolant-Fed Reamers

1. Our “Total Commitment” assures your complete and consistent satisfaction

At Proto-Cutter, “Total Commitment” serves as the foundation for everything we do. There are four areas of our business relationship with you where a commitment to quality is continually stressed.

A commitment to product excellence:

At Proto-Cutter, we consistently utilize only the latest mechanical and computerized inspection equipment, which is applied at every facet of the manufacturing process. This investment in quality control results in tooling that is second to none.

A commitment to superior performance combined with cost efficiency:

We understand that you want the best cutting tool your money can buy, but at a reasonable cost. Proto-Cutter provides the highest quality tools at competitive prices.

A commitment to our responsibility to meet all your needs:

At Proto-Cutter, we do much more than just take orders. We take responsibility by meeting all of your needs in the areas of product design, quality, price and delivery.

A commitment to professionalism:

Professionalism at Proto-Cutter means servicing our customers’ needs quickly and conscientiously, and staying on the cutting edge of technology to consistently produce the finest reamers in the industry. By maintaining our “Total Commitment,” we provide a competitive advantage that will aid you in your marketplace.

2. Custom sharpening results in precise accuracy and exceptional finish

Because we custom sharpen each and every reamer to its exact specified profile and tolerance, you are able to achieve hole size to within .0005”. Hole straightness can be maintained to within .0002”, depending on the hole’s depth and prior operation. With Proto-Cutter reamers, you can achieve a surface finish of 32 RMs, or even better in some circumstances. By achieving this high level of finish, our reamers eliminate the need for time-consuming grinding, honing or burnishing operations. That and dramatically reducing your cost per hole.

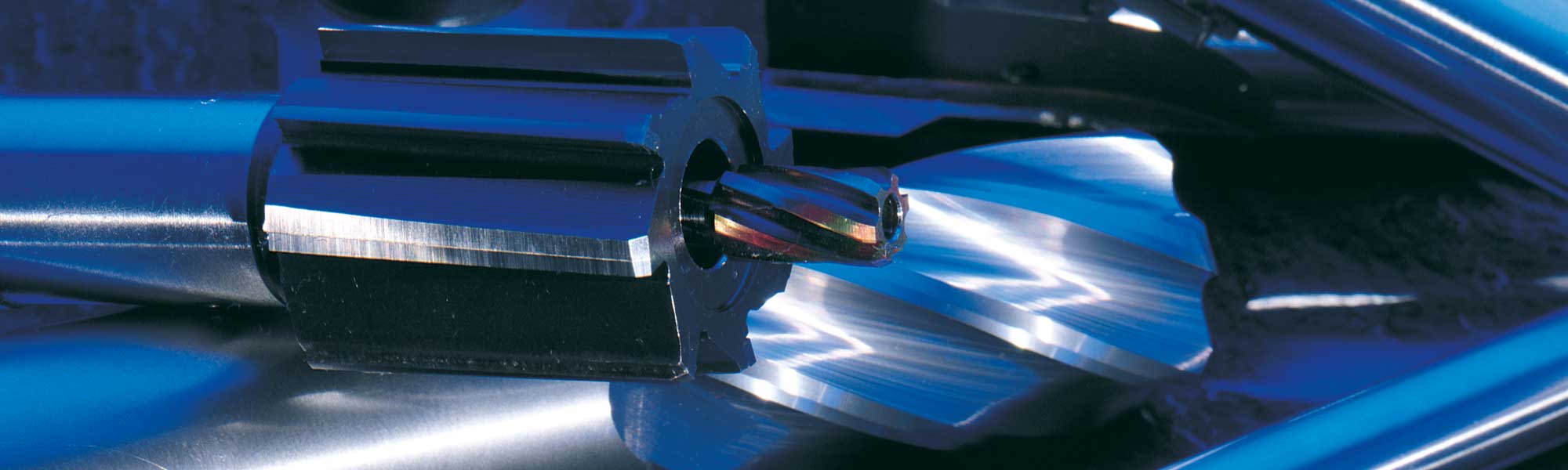

3. Extended tool life means less machine downtime

The unique design of Proto-Cutter reamers extends reamer life significantly over that of conventional reamers, giving you increased tool repeatability and less downtime for more holes reamed per year and increased productivity. Proto-Cutter reamers give you “The Most Value For Your Hole Dollar.”

Carbide-Tipped & Solid Carbide Reamers

Carbide-tipped and solid carbide coolant-fed reamers offer many significant advantages for hole finishing:

• These reamers work well for almost all materials.

• Operation at higher speeds and feed rates increases tool life and decreases cycle time.

• Depending on the application, they can outlast high-speed steel.

High-Speed Steel Reamers

High-speed steel (HSS) reamers are an excellent choice for low cost production jobs:

• They work well with a variety of materials.

• HSS reamers are cost efficient.

• They are great for smaller quantity production runs.

Ready for a Quote?

Choose from our standard reamers or contact us for a custom tooling quote.

4. Quick and consistent on-time delivery means less downtime for you

Our excellent on-time delivery record is consistently better than any of our competitors and means less downtime for you. When you’re in a bind, don’t get behind, pick up the phone and call us.

5. Engineering assistance at no cost makes tool selection easy

Our sales engineers have a broad working knowledge of materials, hardness, feeds, speeds and many other factors that contribute to the performance of the reamer. They will help you choose a reamer and a sharpening profile that will accomplish your hole finishing requirements and productivity goals. Their experience is available without cost or obligation. Just call us.

6. Reconditioning services mean single-sourcing and cost-efficiency

Reconditioning your reamers provides maximum tool life and results in decreased tool costs overall. As your single-source for both new reamers and reconditioning, Proto-Cutter will maximize your tool cost efficiency. In reamer conditioning, we precisely restore the controlled cutting edges through lead sharpening, resizing or replacing carbide tips and sharpening them to the original specifications.

7. Computer data base means quick and accurate re-ordering

We maintain an extensive computer data base file for each customer, recording information such as your tool numbers, reamer sizes, profile selections, and more. With this information readily accessible, each new order you place can be quickly and accurately duplicated.